SDl3 type bulldozer Supporting axle of the original optical axis (see Figure 1), relying on both sides of the ring diameter Ф4mm axial force, bulldozers turning resistance (axial force) large, resulting in group A on the space larger, large diameter O-ring compression force on the floating seal ring inadequate, resulting in oil spills.

Figure 1: Schematic of the original Roller

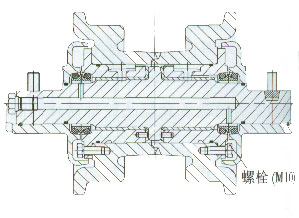

Axis to the new structure will shoulder structure (see Figure 2), by 12 M10 bolts (each side 6) axial force, the floating seal is reliable, able to adapt to a variety of harsh conditions bulldozer. In addition, for the co-axial clearance, tightening torque, group space, large diameter O-ring, floating ring seal, floating seal groove cross-section dimensions and other problems in the optimal design.

Figure 2: Schematic of new rollers

Improved after two years of use, the new roller oil rate decreased from 58.6% down to 5.9%, significantly reducing the failure rate of bulldozers.

Old SDl3 only consider supporting wheels installed to meet the size, not taking into account the adverse conditions, this is the main cause leakage rate. Bulldozers and excavators of different conditions, the three (roller, roller, guide wheel) is also very different structure and excavators. Old SDl3 roller structure similar to the excavator roller structure, new SDl3 supporting wheels on the use of a bulldozer roller classic structure can withstand bulldozer steering resistance (axial force), thus making oil rate.

|